About us

Eco Infra is a company with a vision to offer greener, sustainable, eco-friendly, and futuristic building materials for a better and greener tomorrow.

We are a team of professionals with expertise in construction, interior contracting, building materials, and development, bringing more than 20 years of experience and having delivered thousands of projects with our products and services. Our professional team offers significant expertise in our professional deliverables.

Eco Infra is the first organization of its kind, offering only green building, sustainable, and eco-friendly products, which are crucial for architects, interior designers, civil engineers, builders and developers, government agencies, and patrons who are keen on a better future in architecture.

Products and services offered by Eco Infra deliver energy savings, economical solutions, aesthetic values, high heat insulation, acoustics, and high durability. They are made from natural or recycled materials, have a longer life span, and are easy to install and use. They are organic and do not harm Mother Nature or contribute to landfills post-usage.

Our strategic partnerships with global leaders in these segments help us offer the best-in-class products and services with high performance and durability.

As a society and generation, we carry the responsibility to build and hand over a greener planet and vibrant nature to future generations. That mission can be achieved with greener buildings and sustainable infrastructure.

Our products are LEED Certified, Green Building Certified, Organic, VOC-Free.

Choose responsibly and make our future sustainable.

PROJECTED NATURAL CORK

20

Years of Experience

WHAT IS ECORK

PROJECTED NATURAL CORK

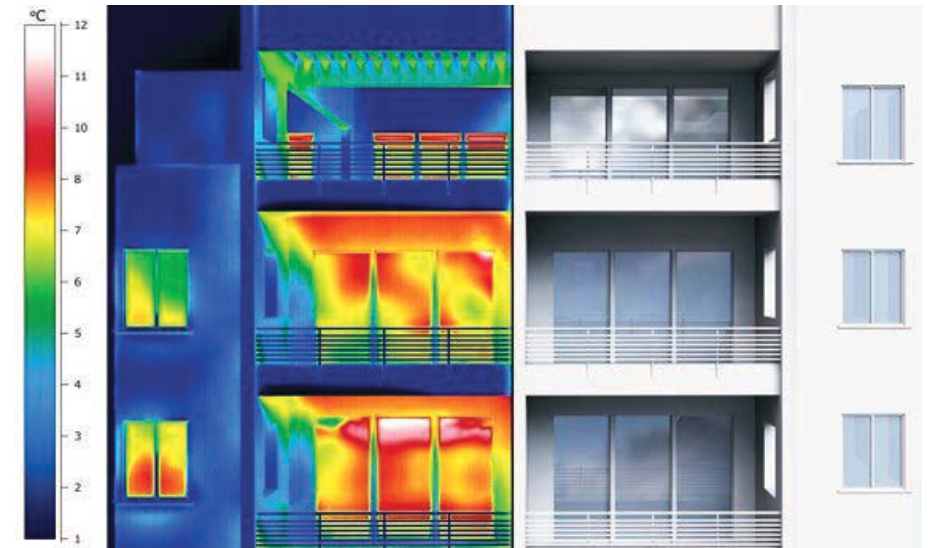

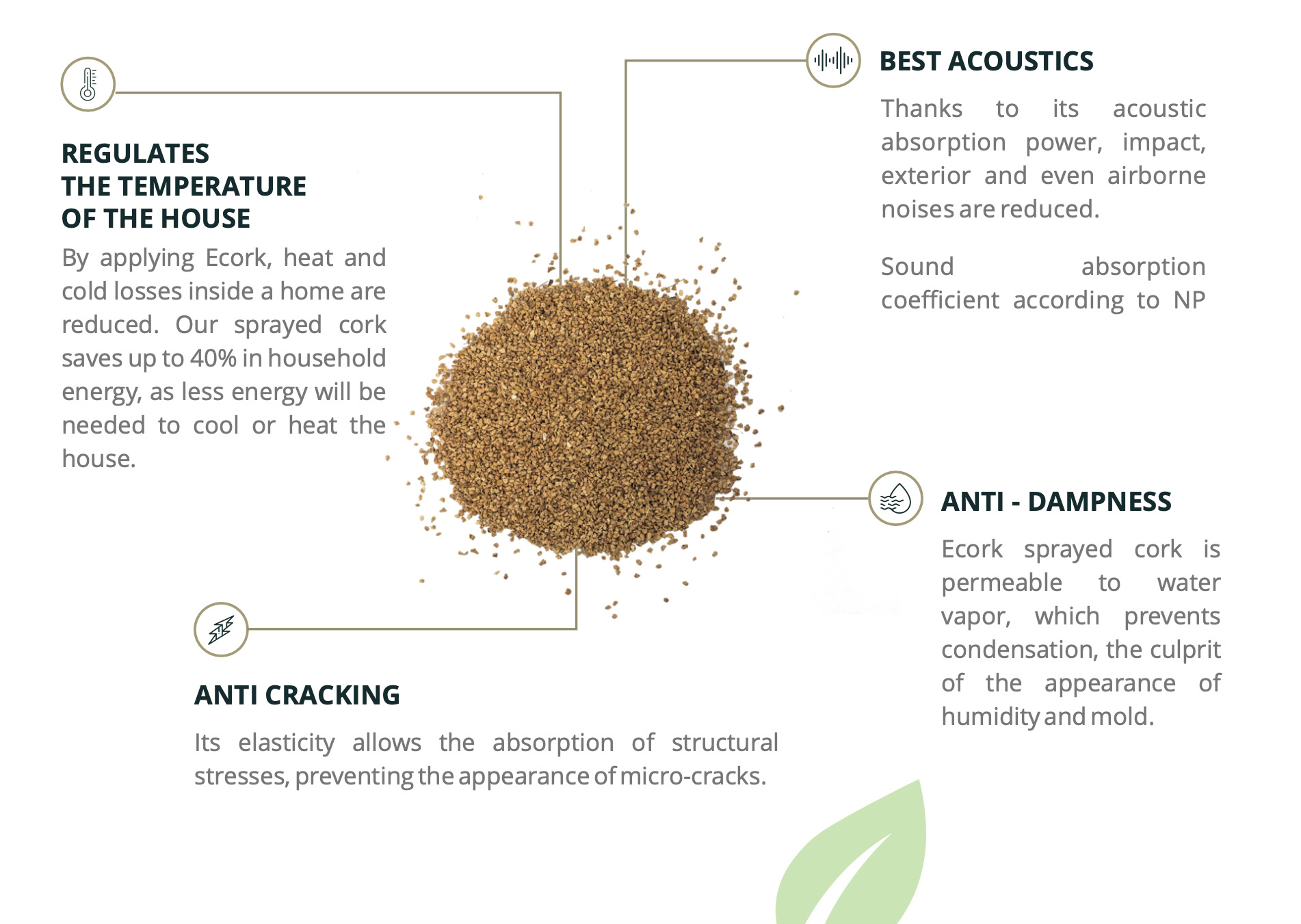

Ecork is characterized, above all, by its high thermal resistance. It acts as a barrier ot the passage of heat between two media that would naturally tend to equalize in temperature.

* Example of thermal conductivities from the highest to the lowest in W/(K•m):

Aluminium = 237 - Wood = 0.13 - Ecork = 0.075

Thermal insulation is one of its main properties, but it is not the only one. Ecork is a coating in great demand due to its many advantages.

Multiple and diverse

ECORK APPLICATIONS

The different ECORK sprayed cork emulsions have total adhesion on most materials (mortar, metal, wood,PVC, expanded polyethylene, fiber cement...) and are suitable as:

a) Humidity and condensation protection in buildings

b) Anti-condensation of sheet metal roofing (dew point)

c) Protection and sealing of air-conditioning ducts

d) Primer between ceramic and mortar

e) Acoustic absorber / reverberation

f) Facade coating

g) Crack sealing

h) Reduction of thermal bridge in columnar foundation

i) Thermal protection of tanks and silos

j) Cold-heat barrier on industrial metal doors

k) Thermal corrector for camper vehicle preparation

l) Roof rehabilitation

m) M Waterproofing “Fine Version” : For all types of roofs (asphalt fabric, sheet metal, fiber cement, etc.), providing in the same application a thermal correction and decorative finsh.

n) Adhesion promoter for slippery floors (wood, sheet metal, ceramic)

o) Thermal corrector in the manufacture of wooden houses or domes

p) Thermal corrector for prefabricated concrete

q) Thermal corrector in the nautical industry

Sustainable Building Materials

ECORK PRODUCTS

Ecork Natural Projected Cork come in 10Kg cubes + 1L of tone.

Within our Ecork range you will find 3 different thicknesses:

Fine, Classic and Rustic.

OUR RANGE OF COLORS

Technical data and tests

CHARACTERISTICS

| REGULATIONS TESTING | RESULTS | |

|---|---|---|

| Specific gravity | EN-ISO 2811-1: 2016 | 0,5-0,7 g/cm3 |

| Grain size | EN-ISO 1524 / UNE EN 1062-1 | 0,5-0,8 mm / S1 Fino |

| Adhesion resistance by pull-off test | EN-ISO 1524: 2000 | ≥ 1,9 N/mm2 |

| Thermal conductivity | UNE-EN 12667 | 0,075 W/m. oC |

| Resistance to artificial weathering | EN-ISO 16474-1: 2014 | No change 3200h |

| Tensile strength and elongation at break | EN-ISO 527-4 | 0,36 Mpa |

| Cross-section | EN-ISO 2409 | Gt0 |

| Crack bridging capability | EN 1062-3:2008 | A1 (-20oC) |

| Thermal compatibility (freeze-thaw cycles) | EN 13687-5 | ≥ 0,8 N/mm2 "No bubbles and cracks" |

| Impact resistance | EN-ISO 6272-1:2012 | W<0,1Kg./m2 h0.5 |

| Capillary absorption and water permeability | EN 1062-3:2008 | 30 minutes At room temperature 20o. |

| Water vapor permeability | EN ISO 7783-1(-2) | Sd< 5m Class I |

| Permeability to CO2 | EN 1062-6 | Sd > 50m |

| Hazardous substances | EN 16516:2018 | Complies with 5.3 |

| Dry to touch (hours) | UNE 48301 : 1999 | 4-5 |

| Second coat (hours) | UNE 48301 : 1999 | 24 |

| Coverage (m2/L) | UNE 48282 : 2017 | 1,8 - 2 Kg/m2 |

| Volatile organic compounds (VOC) | UNE EN ISO 17895 | Maximum product content 15 |

| Sound absorption | EN ISO 354:2004 | aw = 0,10 |

Eco Infra holds a strategic partnership with Kilnher Group (Spain). Ecork is manufactured by Kilnher and marketed by Eco Infra.